In the business of slippers wholesale and customization, “MOQ” is the buzzword that almost every B2B buyer has heard of or come across. Whether you are a cross-border e-commerce brand seeking an OEM Slipper factory for the first time, a wholesaler with sales channels looking to customize and differentiate your products through the means of ODM Slippers, or an importer who wants to test the market quickly with Ready Stock Slippers, grasping the logic of Slipper MOQ will directly benefit your procurement expenses, delivery time control and inventory risk.

For household items such as PVC/EVA slippers, MOQ is more complicated than a simple “minimum order quantity” sheet; other factors associated are mold cost, raw material ordering, production schedule, degree of customization of products, and factory business model. According to three typical models: OEM, ODM, and ready stock, this article will analyze the causes of why the formation of Slipper MOQ is suitable in certain scenarios and purchasing strategies, supporting you in more efficient and professional discussions with slipper manufacturers.

How is the MOQ for OEM Slippers Determined?

の中で OEM Slipper model, buyers usually have a clear product design plan, such as shoe structure, upper pattern, color matching, logo placement, and even packaging solutions. The factory primarily plays the role of “manufacturing according to the design.” The Slipper MOQ in this model is usually strongly correlated with the following factors:

First, mold and process costs. Taking PVC or EVA slippers as an example, if the customer requires a brand-new sole mold or special anti-slip patterns, the factory needs to invest in mold costs in advance. To spread these costs, the MOQ is often set between 800 and 3000 pairs. For basic flip-flops or flat slippers, the OEM Slipper MOQ is relatively low; however, if it involves Crocs shoes or functional thick-soled slippers, the MOQ will increase significantly.

Secondly, the raw material procurement threshold. PVC and EVA raw materials usually need to be purchased in tons, and different colors and formulations mean higher minimum quantities. If an order has too many colors and too few quantities per color, even if the total quantity reaches the Slipper MOQ, the actual production cost will increase, which is why many factories insist on the MOQ. For B2B buyers, practical tips for choosing OEM slippers include:

- Minimize the number of colors in the initial order.

- Use existing, proven shoe designs from the factory with minor adjustments.

- Place larger orders only after confirming market feedback.

This approach meets the slipper MOQ requirements while effectively controlling initial investment risks.

ODM Slippers: Seemingly Flexible, but Still Subject to MOQ Logic

Many buyers believe that the MOQ for ODMスリッパ is always lower than for OEM, but this isn’t entirely true. In the ODM model, product design is led by the factory, and buyers customize or make minor modifications based on existing designs. While this does reduce development costs, the slipper MOQ is still influenced by multiple factors.

From an advantage perspective, ODM slippers usually don’t require new molds. Factories provide a library of mature shoe designs, such as EVA sports sandals, Crocs-style clogs, and children’s garden shoes. The MOQ for these products is often between 300 and 1000 pairs, making them ideal for small and medium-sized brands or for testing new markets.

However, it’s important to note that ODM doesn’t mean “unlimited modifications.” If buyers propose significant structural changes to existing designs, such as altering sole thickness, adding special anti-slip features, or redesigning the upper proportions, the process may become similar to OEM, and the slipper MOQ will increase accordingly.

In actual procurement, the key to successfully utilizing ODM slippers is:

- Prioritize factory best-sellers or long-term production models.

- Focus customization on colors, logos, and packaging.

- Confirm in advance which modifications will not affect the MOQ.

For B2B customers who want to quickly establish a product line while maintaining a degree of differentiation, ODM slippers strike a good balance between cost and brand building.

Ready Stock Slippers: Lowest MOQ, but Also the Most Limitations

Ready Stock Slippers refer to slipper products that the factory has already produced and has in stock. In this model, the slipper MOQ is usually the lowest, sometimes even supporting orders as low as 50-100 pairs, making them ideal for e-commerce sellers, wholesalers, or buyers in the sample testing phase.

The core advantages of Ready Stock Slippers are fast delivery times and lower capital requirements. Buyers don’t need to wait for production cycles; shipments can be arranged immediately after confirming the style, which is especially important during peak seasons or promotional periods. This is a very efficient approach for customers who want to quickly validate market demand.

However, the limitations are also obvious. Ready-stock slippers have limited options in terms of color, size ratios, and shoe design, and usually cannot be deeply customized. LOGO customization is mostly limited to labeling and simple printing, which is not suitable for customers with high demands on brand image.

Practical suggestions:

- Use Ready Stock Slippers for market testing

- Collect end-user feedback data

- Then upgrade to ODM or OEM Slipper models

This strategy of “progressing from low MOQ to high customization” is being adopted by more and more mature buyers.

Cost and Risk Comparison Behind Different Slipper MOQs

From a procurement decision perspective, a lower Slipper MOQ is not always better; it needs to be evaluated comprehensively based on unit price, inventory turnover, and brand stage.

- OEM Slippers: Suitable for mature brands, controllable unit price, high MOQ but unique product

- ODM Slippers: Suitable for growing customers, balancing MOQ and customization flexibility

- Ready Stock Slippers: Suitable for trial orders and quick turnover, lowest MOQ but weak differentiation

Data shows that in PVC/EVAスリッパ export orders, about 60% of new customers choose Ready Stock or ODM Slippers for their first order, while the proportion of OEM Slippers increases significantly in repeat orders. This indicates that the choice of Slipper MOQ is essentially a reflection of the brand’s development stage.

Conclusion: How to Choose the Most Suitable Slipper MOQ for You?

Understanding Slipper MOQ is not just about “negotiating prices” with factories, but about establishing a longer-term, stable supply chain relationship. OEM Slippers, ODM Slippers, and Ready Stock Slippers each correspond to different business objectives and risk tolerance levels.

If you pursue brand uniqueness and scale, OEM is the necessary path; if you want to quickly launch and control costs, ODM is the ideal choice; if you want to test the market with low risk, Ready Stock Slippers are undoubtedly the best starting point. The key is to make a rational choice based on your own stage, rather than simply pursuing the lowest MOQ.

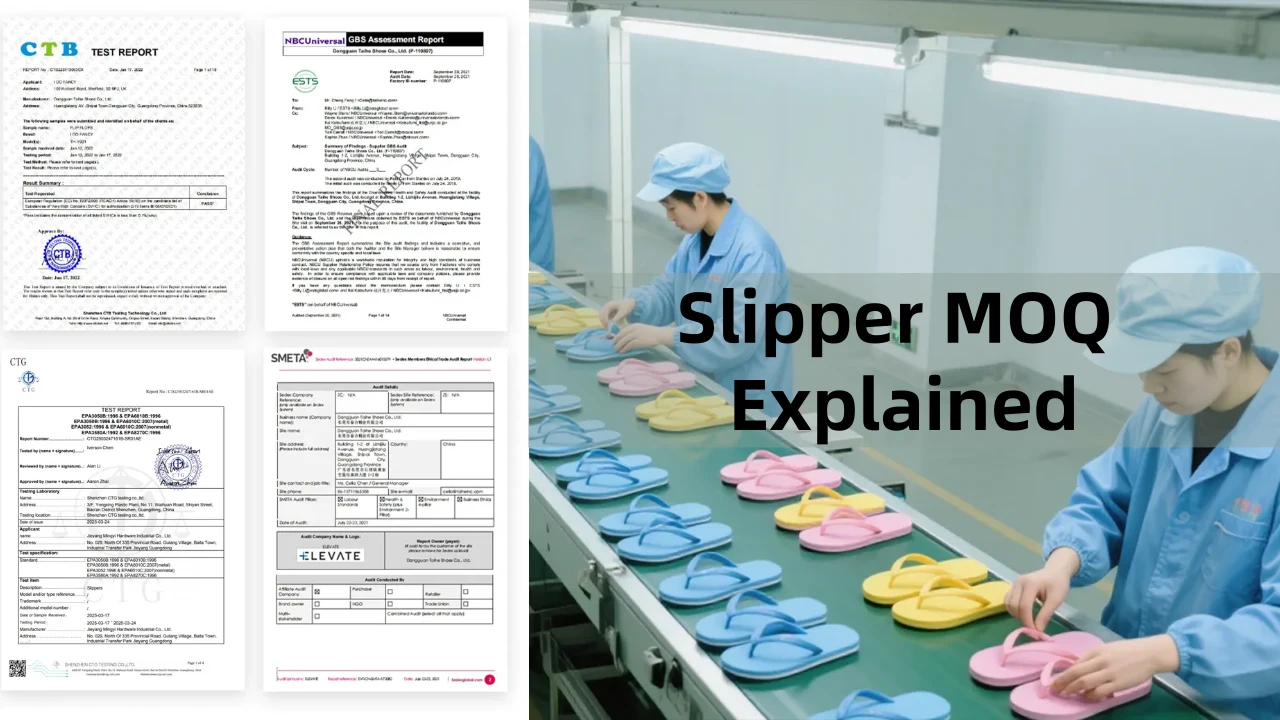

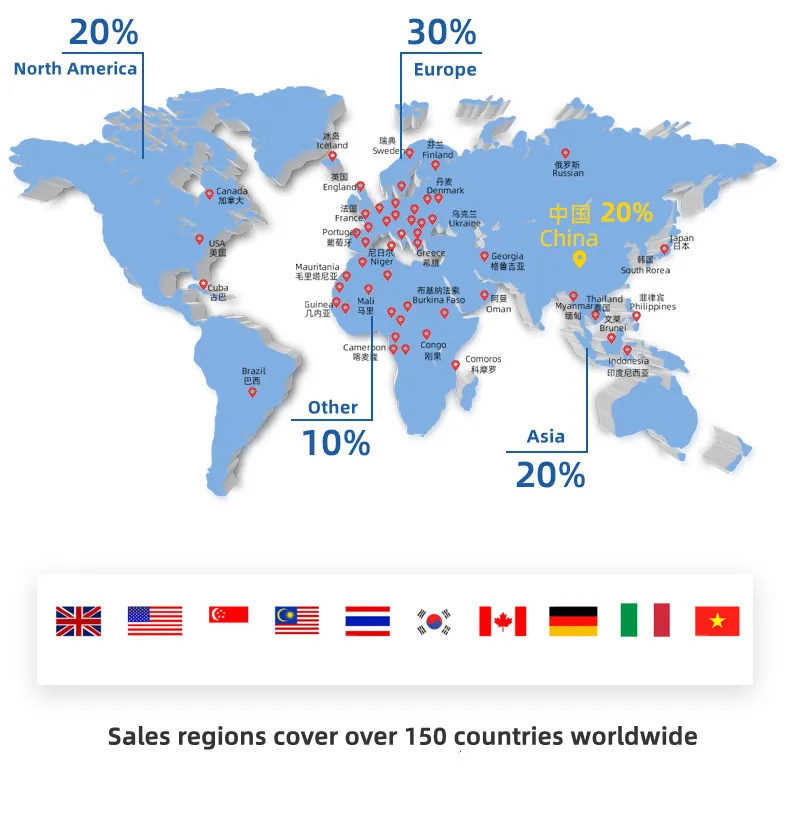

Mingyiについて|PVC/EVAスリッパの専門メーカー

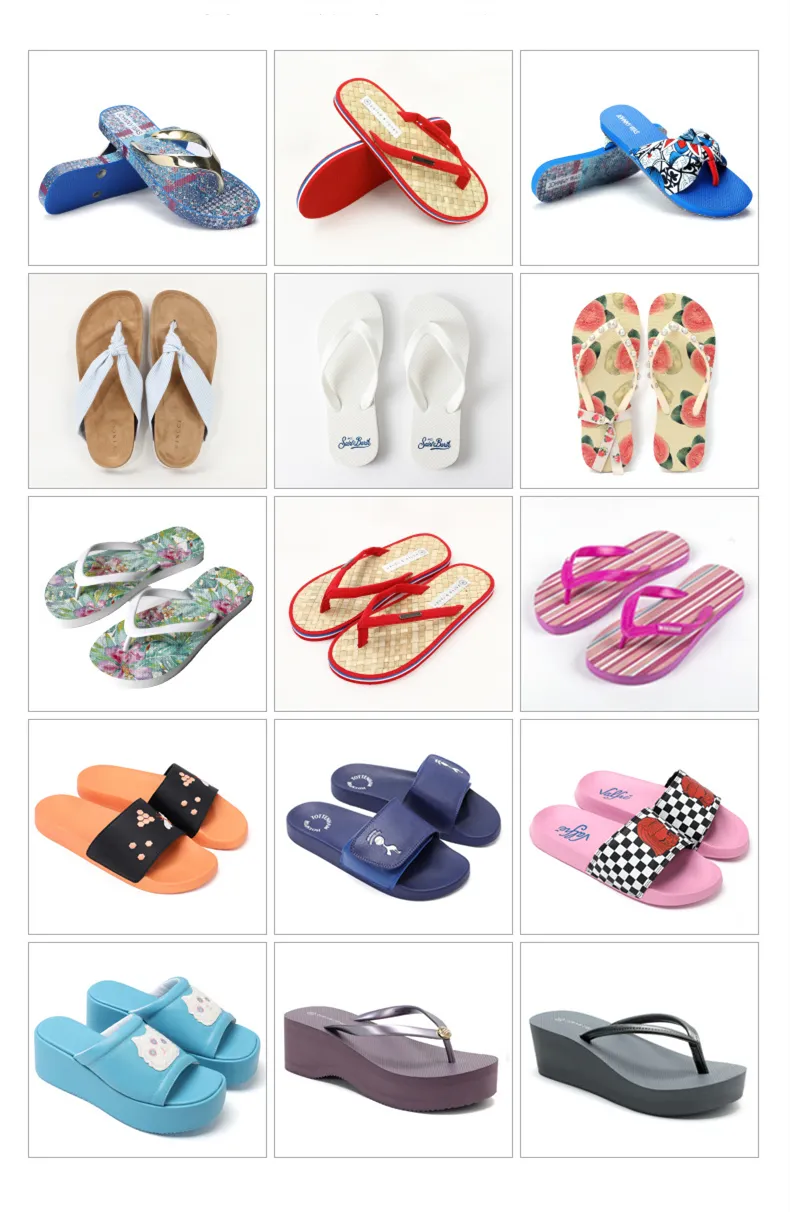

揭陽 ミンイー をリードしている。 PVC/EVAスリッパメーカー の研究開発と生産に特化している。 OEMスリッパ, ODMスリッパそして ready-stock slippers. Our products include PVC slippers, EVA slippers, Crocs shoes, flip-flops, sandals, as well as slipper accessories and Crocs charms, meeting the needs of different markets and channels.

ミンイー boasts a mature mold system, a stable raw material supply chain, and flexible slipper MOQ solutions, supporting ワンストップOEM/ODMサービス from design and prototyping to large-scale delivery, helping brand customers quickly launch products and seize market opportunities.

FAQ: Slipper MOQ Frequently Asked Questions

Q1: Can the slipper MOQ be lowered for the first cooperation?

A: In some cases, yes. Choosing ODM or ready-stock slippers can usually effectively lower the initial order MOQ, facilitating market testing.

Q2: Are OEM slippers always more expensive than ODM slippers?

A: The unit price is not necessarily higher, but the initial mold and MOQ requirements are higher, making it suitable for customers with stable sales volumes.

Q3: Can ready-stock slippers be customized with a brand logo?

A: Basic logo and packaging customization is possible, but deep modifications to the structure and shoe style are not supported.