Introduction: Why is Anti-Yellowing Technology Increasingly Important for PVC Slippers?

In the world wholesale and retail market for slippers, PVC slippers continue to be one of the best sellers. Due to its low cost, high plasticity, rich colors, waterproof, and wear-resisting properties, it is popular in home slippers, hotel slippers, garden slippers, children’s slippers, leisure casual slippers and other aspects. But as competition in the market heats up, being “cheap and easy to sell” is not enough to satisfy the needs of both B2B customers and consumers at the end of the supply chain.

One problem attracting more and more interest of the brands, the importers, as well as the wholesalers is the yellowing issue of pvc slipper. Yellowing not only affects the appearance but also directly reduces the product quality, increases the return rate and the loss of brand reputation, especially is more obvious in light-colored/white/transparent PVC slippers. For cross-border e-commerce, brand owners, and chain retailers, anti-yellowing has been regarded as a sign of a supplier’s technology capability and product quality.

Through reasonable design and selection of raw materials, safe additives, suitable production processes, reliable testing standards, and source procurement management, the anti-yellowing technology of PVC Slippers is presented in this article in a multi-angle analysis. It gives an overview of which key points retailers and brands should focus on when choosing suppliers in order to minimize risk and improve market competitiveness.

What Causes PVC Slippers to Yellow? Basic Principles Retailers Must Understand

Before assessing the anti-yellowing performance of PVC slippers, retailers first need to understand the root causes of yellowing. PVC material itself is not naturally stable; it is highly susceptible to color changes under specific conditions.

1. Material Aging is the Core Factor of Yellowing

During processing and use, PVC is continuously affected by ultraviolet light, oxygen, heat, and humidity. When the molecular structure changes, visible yellowing occurs. The risk of yellowing in PVC slippers increases significantly, especially during high-temperature summer transportation, shipping containers, or long-term storage.

2. Inferior Additives and Unstable Formulations

Some low-priced PVC slippers use low-cost stabilizers or recycled materials. These materials may not show problems in the short term, but they are highly prone to noticeable yellowing after 3-6 months. For B2B customers, this means after-sales risk and inventory pressure.

3. The Amplifying Effect of Color Design on Yellowing

Light-colored, white, transparent, or pastel-colored PVC slippers are extremely sensitive to yellowing. Even slight yellowing will be quickly noticed by consumers. Therefore, fashion, children’s shoes, and high-end custom PVC slippers have higher requirements for anti-yellowing technology.

Retailer’s Key Takeaway: If a supplier cannot clearly explain the causes and solutions for PVC slipper yellowing, it often means they lack systematic experience in materials and technology.

Core Technology of Anti-Yellowing PVC Slippers: Starting with Formulation

Truly high-quality PVC slippers do not rely on a single step for anti-yellowing capabilities; rather, the anti-yellowing ability is determined from the raw material formulation design stage.

1. High-Performance Stabilizer System

High-quality PVC slippers typically employ a complex heat stabilizer and light stabilizer system to slow down the decomposition of PVC molecular chains under high temperatures and UV radiation. Data shows that PVC slippers with added professional UV-resistant stabilizing systems can reduce yellowing index by 30%–50%.

2. Dual Design for Antioxidation and UV Protection

Single antioxidant protection is insufficient to cope with complex distribution environments. Experienced manufacturers incorporate a combination of antioxidants and UV absorbers into their PVC slipper formulations, reducing the likelihood of color changes at the source.

3. Virgin vs. Recycled Materials

Extensive practical experience shows that PVC slippers using a high proportion of virgin PVC material are significantly superior to products made from high-recycled materials in terms of yellowing resistance, odor control, and physical properties. For brand customers, choosing factories that adhere to raw material standards is key to reducing after-sales issues.

Purchasing Recommendations: Retailers can request suppliers to provide formulation principles or material grade specifications for PVC slippers, as this is an important reference for determining their resistance to yellowing.

How Does the Manufacturing Process Affect the Yellowing Resistance of PVC Slippers?

Even with a high-quality formulation, PVC slippers may still experience premature yellowing if the manufacturing process is not properly controlled.

1. Temperature Control and Processing Time Management

PVC is extremely sensitive to temperature during processing. Excessively high processing temperatures or excessively long heating times will accelerate material aging. Professional PVC slipper manufacturers use automated temperature control systems to keep the error within ±2℃.

2. Mold and Molding Process

An unreasonable mold structure can lead to localized overheating, resulting in “hidden yellowing spots.” In high-end custom PVC slippers, mold designs are often optimized separately for light-colored or highly transparent styles.

3. Surface Treatment and Post-Processing

Some PVC slippers undergo surface coating or polishing processes to further enhance their resistance to yellowing and staining. While these processes increase costs, they significantly extend the product’s market life, making them particularly suitable for mid-to-high-end channels.

B2B Value Points: Stable processes mean higher batch consistency, facilitating long-term brand replenishment and series sales.

IV. How to Determine if PVC Slippers Truly Resist Yellowing?

For retailers and brands, the most important question is: how to determine during the procurement stage whether PVC slippers are “truly resistant to yellowing”?

1. Accelerated Aging Test

Professional manufacturers typically conduct UV aging tests, high-temperature aging tests, and damp heat tests. Generally, high-quality PVC slippers maintain acceptable color changes after 72–120 hours of accelerated aging.

2. Yellowing Level Assessment

The industry commonly uses grayscale or ΔE color difference values to assess the degree of yellowing in PVC slippers. Retailers can request relevant test data or third-party testing reports from suppliers.

3. Real-world Market Case Validation

More important than specifications are market feedback from long-term clients. Established suppliers can often provide application cases of PVC slippers in different countries and under different climatic conditions.

Practical Tip: Before placing a bulk order, it is recommended to conduct sun exposure tests or simulated warehouse storage tests on samples. This is an effective way to reduce risk.

Key Considerations for Retailers When Selecting Anti-Yellowing PVC Slipper Suppliers

To ensure PVC slipper maintain a consistent appearance throughout their sales cycle, retailers should focus on the following points when selecting suppliers:

- Does the supplier specialize in PVC/EVA slippers production, rather than miscellaneous products?

- Does the supplier possess clear anti-yellowing technology solutions and testing procedures?

- Does the supplier support customized adjustments for color, material, and structure?

- Can the supplier meet the climate requirements of the target market (Europe, America, Southeast Asia, the Middle East, etc.)?

- Does the supplier have stable delivery times and the ability to control bulk order consistency?

In the long run, anti-yellowing performance is not only a technical issue but also part of brand asset management. Choosing the right PVC slippers manufacturing partner means lower after-sales costs and higher customer repurchase rates.

Conclusion: Anti-yellowing is the essential path for PVC slippers to enter the mid-to-high-end market

As the global slipper market continues to upgrade, PVC slippers are evolving from “basic daily necessities” to “functionality + design + quality.” Yellowing has become a significant obstacle limiting the branding and premium pricing power of PVC slippers.

Through scientific material formulation, stable production processes, and a rigorous testing system, anti-yellowing PVC slippers can fully meet the needs of long-term sales and cross-regional distribution. For retailers and brands, a deep understanding of anti-yellowing technology can not only help make more informed purchasing decisions but also establish a differentiated advantage in the fierce market competition.

About Mingyi: A Professional PVC/EVA Slipper Manufacturer

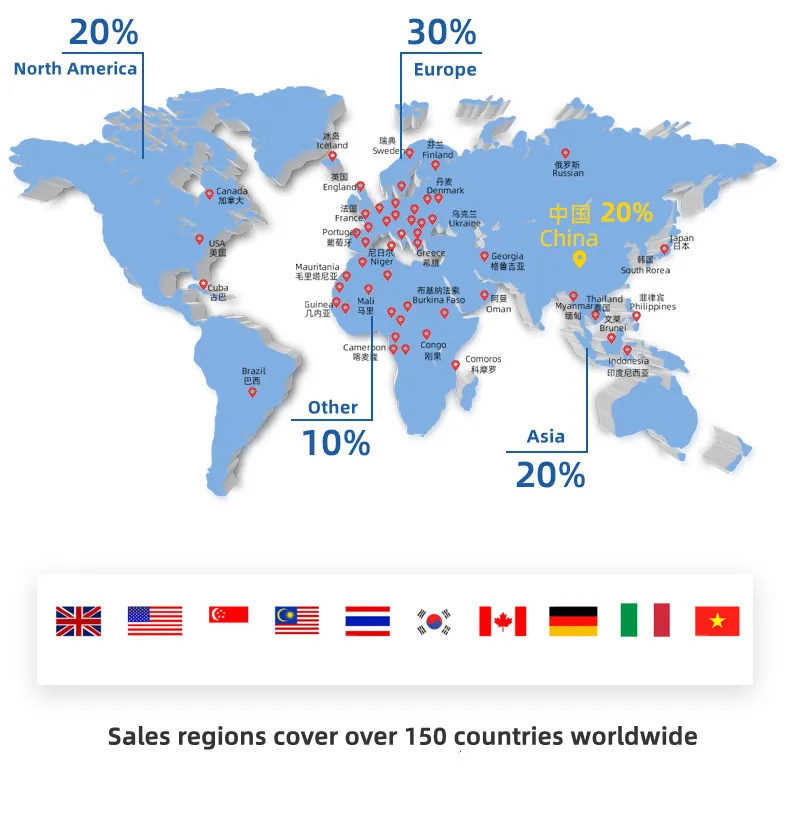

Jieyang Mingyi is a leading PVC/EVA Slipper Manufacturer in China, specializing in the research and development and production of PVC/EVA slipper. We provide professional wholesale and customization services for slippers to global clients, covering PVC slippers, EVA slippers, Crocs shoes, flip-flops, sandals, slipper accessories (sole and upper), Crocs charms, etc., meeting the needs of different markets and channels.

Mingyi has developed a mature anti-yellowing technology system and can customize various styles, colors and functions for the men, women, and children markets. We provide one-stop OEM/ODM service from design and sampling to mass delivery, assisting brand clients to shorten lead time, minimize risk, and fast ship, which makes us your dependable long-term slipper manufacturer partner.

FAQ

Q1: Will light-colored PVC slipper always yellow?

Not necessarily. By optimizing material formulations, using UV stabilizers, and controlling production processes, light-colored PVC slippers can also have good anti-yellowing properties.

Q2: Are anti-yellowing PVC slipper significantly more expensive?

Compared to regular PVC slippers, the cost is slightly higher, but it significantly reduces return rates and after-sales risks, resulting in a higher overall cost-performance ratio.

Q3: Which markets are suitable for high-end sales of PVC slipper?

In the European, American, Japanese, and Middle Eastern markets, high-quality, yellowing-resistant slippers in PVC are more likely to enter mid-to-high-end retail channels.